In this article:

Our Shade House Designs: # Farmers Friend

Revised Shade House Proposal for SPA.GD Soursop Propagation

1. General Dimensions and Layout

- Width: 16 feet

- Length: 120 feet

- Height: Minimum 2 meters (6.5 feet) from base to highest beam, ensuring ample airflow and space for plants and working areas.

2. Structural Frame

- Material: Galvanized steel with a solid ground fixing system, using L-shaped anchors for extra stability, particularly important in the Caribbean climate prone to storms(Minimum Requirements fo…).

- Foundation: Concrete blocks or deep-set steel posts will secure the frame in the ground, ensuring durability against high winds and hurricanes(Minimum Requirements fo…).

3. Shade Mesh

- Material: High-density, water-permeable polyethylene knitted mesh, resistant to UV rays, chemicals, and weathering.

- Shade Percentage: The mesh will provide 50-60% shade, reducing heat accumulation and wind impact while maintaining proper light levels for plant growth(Minimum Requirements fo…).

- Removable Panels: Separate, easy-to-replace sections of the mesh will allow for fast repairs or removal during extreme weather conditions(Minimum Requirements fo…).

- Color: Black or green mesh, UV-resistant, with a lifespan of up to 10 years(Minimum Requirements fo…).

4. Flooring

- Type: Well-draining gravel or raised beds with organic-rich soil to prevent waterlogging. Gravel paths will be laid between planting rows and workstations for ease of movement and maintenance.

- Drainage System: A simple drainage system will be installed to manage excess water from irrigation and rain.

5. Irrigation System

- Automated Drip Irrigation: A drip irrigation system will be installed, ensuring that plants receive consistent moisture levels without overwatering.

- Water Storage Tanks: Tanks will be connected to the irrigation system for efficient water usage, especially during dry periods.

6. Climate Monitoring and Ventilation

- Climate Control System: Sensors will monitor temperature, humidity, and soil moisture. This data will inform irrigation schedules and alert operators to any significant environmental changes.

- Ventilation: Natural ventilation will be enhanced through the shade mesh, with strategically placed openings to prevent excess humidity, reducing the risk of fungal infections.

7. Cutting Tables and Workstation Layout

- Workstation Area: A dedicated working space for cutting tables and plant preparation will be placed at one end of the shade house, covering approximately 20 feet of the length. Tables will be sturdy, weather-resistant, and easily accessible.

- Cutting Tables: Approximately 4-6 cutting tables, each measuring 6 feet by 2.5 feet, will be installed to accommodate workers preparing plant cuttings.

- Tool Storage: Lockable storage cabinets will be installed for rooting powder, cutting tools, and irrigation supplies.

8. Waste and Water Management

- Compost Area: A small composting section near the working area will handle plant waste, ensuring it is recycled and used to enrich the soil.

- Runoff Management: A system of drainage channels will direct excess water away from the growing area, preventing flooding.

9. Security and Access Control

- Fencing: A perimeter fence with a gated entrance will secure the shade house, protecting the plants from unauthorized access.

- Locking Mechanisms: Lockable doors will be installed on any storage spaces and access points to protect equipment and plants.

10. Hurricane Preparedness

- Anchoring: The structure will be anchored with deep concrete or steel posts to resist high winds.

- Removable Shade Mesh: Mesh panels will be easy to detach in preparation for hurricanes, allowing wind to pass through the structure without causing damage(Minimum Requirements fo…).

11. Lighting

- Supplemental Lighting: Energy-efficient LED lights will be installed to extend working hours during low light conditions or cloudy days, enhancing the productivity of the workers in the cutting area.

Cost Breakdown (Estimated)

| Item | Description | Cost (USD) |

|---|---|---|

| Frame Structure | Galvanized steel frame with ground fixing system | $30,000 |

| Shade Mesh | 50-60% shade, UV-resistant polyethylene mesh | $15,000 |

| Concrete Foundation/Anchoring | Deep concrete/steel post anchoring for hurricane protection | $8,000 |

| Automated Drip Irrigation System | Complete irrigation setup with water storage tanks | $10,000 |

| Workstations and Cutting Tables | 4-6 cutting tables, weather-resistant material, and tool storage | $5,000 |

| Climate Monitoring System | Temperature, humidity, and moisture sensors | $7,000 |

| Ventilation and Lighting | Natural ventilation and LED lighting for extended working hours | $3,000 |

| Security and Fencing | Perimeter fencing, gates, and lockable storage | $5,000 |

| Waste and Water Management | Drainage system, compost area, and runoff management | $4,000 |

| Hurricane Preparedness | Removable shade mesh panels and reinforced anchoring | $6,000 |

| Miscellaneous and Contingency | For unexpected costs and minor adjustments | $5,000 |

| Total Cost | $98,000 |

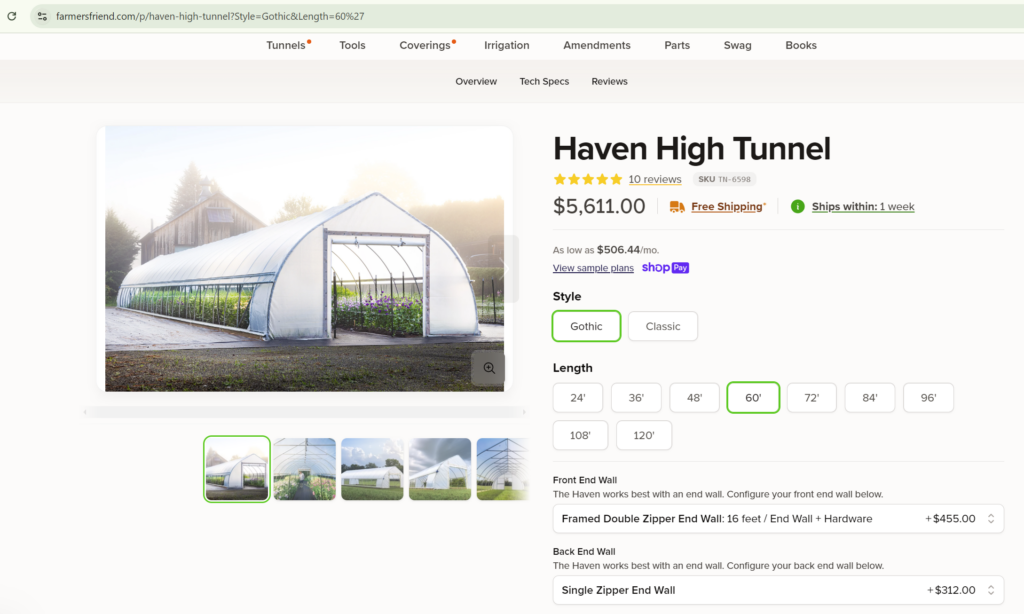

Bill of Quantities (BoQ) for ( 16 Wide by 60 long) 60-Foot Greenhouse Shade House

:

| Item | Description | Quantity | Unit | Cost (USD) |

|---|---|---|---|---|

| 1. Ground Preparation and Site Work | ||||

| Ground Clearance | Tractor clearing and flattening of the area | 1 | Job for SPA | $1,500 |

| Concrete Works (External) | Concrete works for the area outside the greenhouse | 1 | Job for SPA | $3,000 |

| Gravel and Compacted Material | Internal area preparation with gravel and compact material | 1 | Job for SPA | $2,000 |

| Total for Ground Preparation | $6,500 | |||

| 2. Foundation and Ground Posts | ||||

| Ground Posts (Galvanized, 14-gauge steel) | Securing structure to the ground | 62 | Pieces | |

| 3. Structural Frame | ||||

| Gothic Center Bow Sections (14-gauge) | Form the curved roof structure for stability | 31 | Pieces | |

| Side Bow Sections (14-gauge) | Connect bow sections at the sides | 62 | Pieces | |

| 4. Purlin and Crossbars | ||||

| Center Purlin (72-inch) | Run along the top, connecting bows | 19 | Pieces | |

| Crossbars (88-inch) | Provide lateral support to the structure | 29 | Pieces | |

| 5. Baseboards | ||||

| Wood Baseboards (72-inch) | Secure base of the structure to the ground | 40 | Pieces | |

| 6. Fasteners and Connectors | ||||

| Self-Tapping Screws | Attach components (bows, purlins, crossbars) | 697 | Pieces | |

| Wood Screws (Galvanized) | Secure baseboards and other wooden components | 648 | Pieces | |

| Double-Channel Bolts | Secure the double-channel system | 196 | Pieces | |

| Double-Channel Nuts | Paired with bolts to secure the channel system | 196 | Pieces | |

| Double-Channel Tube Straps | Secure purlins and components to the structure | 58 | Pieces | |

| 7. Plastic Sheeting and Panels | ||||

| Greenhouse Plastic (UV-resistant) | Plastic sheeting to cover the entire structure | 1 | Roll | |

| Plastic Corner Panels (5ft x 5ft) | Reinforce corners of the greenhouse | 4 | Pieces | |

| 8. Channel System | ||||

| Double Wire Channel (Galvanized) | Holds plastic sheeting on the frame | 40 | Pieces | |

| Single Wire Channel (47-inch) | Secure the plastic at various points | 12 | Pieces | |

| Spring Wire | Secures plastic in the channel system | 144 | Pieces | |

| 9. Roll-up Side Walls | ||||

| Roll-Up Bars (Galvanized) | Roll-up sides for ventilation control | 40 | Pieces | |

| 10. Hand Cranks | ||||

| Side Wall Hand Crank (Right) | Manually raise and lower the roll-up sides | 1 | Piece | |

| Side Wall Hand Crank (Left) | Manually raise and lower the roll-up sides | 1 | Piece | |

| 11. Anti-Billow Ropes | ||||

| Rope Nylon Cord (375-ft spool) | Prevents plastic from billowing in high winds | 1 | Spool | |

| 12. Miscellaneous | ||||

| Finishing Caps (Rubber) | Protect exposed bolts | 4 | Pieces | |

| Ground Post Driver | Tool for driving ground posts | 1 | Piece | |

| Baseboard Splice Plates | Connect baseboards end-to-end | 20 | Pieces | |

| Tools | Drill bits, socket wrenches, wire cutters, etc. | 1 | Set | |

| 13. Overhead Irrigation System | Suitable overhead irrigation system for 120-foot greenhouse | 1 | System | $1,500 |

| 14. Workstation (Stainless Steel Tables and Tools) | ||||

| Stainless Steel Tables (6ft x 2.5ft) | Work tables for chemical storage and plant cutting | 2 | Pieces | $2,500 |

| Chemical Storage Cabinet | Lockable cabinet for secure storage of chemicals | 1 | Piece | $500 |

| Plant Cutting Tools | Includes shears, knives, pruning tools, and rooting powder | 1 | Set | $800 |

| Safety Gear | Gloves, goggles, and aprons for handling chemicals and plants | 1 | Set | $300 |

| Total for Workstation and Tools | $4,100 |

Summary of Additional Costs:

- Ground Clearance with Tractor: USD $1,500

- Concrete Works (External Area): USD $3,000

- Gravel and Compacted Material (Internal Area): USD $2,000

- Overhead Irrigation System: USD $1,500

- Stainless Steel Tables, Chemical Storage, and Plant Cutting Tools: USD $4,100

- The Shade house ( Full component without installation ) ( 16 x 60 feet) USD $8500.00 + Shipping to Grenada USD3500.00 = USD$12,000.00

The grand total for the project is USD $24,100 per shade house for the planting of the sour sop plant using our method. ( Click here to see the method) About 2000 planting per season.

Our Model for Sustainability

Approach for Greenhouse Design, Build, Procurement, and Installation for Tree Crops

The following approach outlines the process for designing, building, procuring, and installing greenhouses specifically for tree crop cultivation. The process is divided into key stages to ensure a comprehensive, efficient, and sustainable solution.

1. Project Planning and Feasibility Study

Before initiating the design and build process, it is essential to conduct a feasibility study to assess the project’s viability and requirements:

- Site Analysis: Assess the selected site for soil quality, access to sunlight, wind conditions, water availability, and drainage. Evaluate local climate conditions to ensure suitability for tree crops.

- Crop Selection: Identify the types of tree crops (e.g., soursop, citrus, avocado) to determine specific growing requirements such as space, temperature, and irrigation needs.

- Regulatory Compliance: Review local building regulations and agricultural standards to ensure the greenhouse structure and operations meet all necessary requirements.

- Budget and Funding: Establish a detailed project budget, including all phases: design, procurement, construction, and installation. Secure necessary funding.

2. Greenhouse Design and Customization

Designing the greenhouse involves creating a structure that meets the specific needs of tree crops while optimizing energy use, water conservation, and environmental control:

- Structure Design:

- Choose an appropriate greenhouse frame (galvanized steel, aluminum) that can withstand the local weather conditions.

- Design the structure to accommodate the growth of tree crops, ensuring adequate height and spacing for mature trees.

- Incorporate natural ventilation systems such as roll-up side walls, vents, or automated fans.

- Integrate shade cloths or UV-resistant coverings to control sunlight exposure and temperature.

- Climate Control:

- Design an efficient climate control system (temperature, humidity, and airflow) suited for tree crops.

- Incorporate heating and cooling systems if necessary, depending on the local climate.

- Irrigation System:

- Develop an overhead or drip irrigation system customized for the type of tree crop being cultivated.

- Include automated irrigation and moisture sensors to optimize water usage.

- Planting and Growing Area:

- Design adequate planting space and pathways for tree crops, ensuring accessibility for pruning, harvesting, and maintenance.

- Plan for specialized areas such as cutting tables, workstations, and chemical storage for crop management.

- Energy Efficiency:

- Explore renewable energy options, such as solar panels, to reduce energy consumption for irrigation, climate control, and lighting.

3. Procurement of Materials and Equipment

The procurement phase focuses on acquiring the necessary materials, equipment, and services to build and operate the greenhouse:

- Greenhouse Frame and Covering:

- Procure high-quality galvanized steel or aluminum frames, ensuring durability and resistance to local climate conditions.

- Source UV-resistant polyethylene covers or shade cloths with appropriate shading percentages for the selected tree crops.

- Irrigation System:

- Purchase a customized irrigation system, including overhead sprinklers, drip lines, pumps, and moisture sensors.

- Climate Control and Ventilation:

- Acquire ventilation components such as roll-up side walls, exhaust fans, and thermostats to regulate the greenhouse environment.

- Workstation Equipment:

- Procure stainless steel tables, cutting tools, and chemical storage cabinets for tree crop preparation and care.

- Construction Materials:

- Source materials for concrete work, foundation installation, and gravel compaction for the internal and external areas.

- Shipping and Logistics:

- Plan for logistics and shipping of all components to the project site, accounting for customs and transportation time.

4. Build and Installation Process

This phase involves the actual construction and installation of the greenhouse on-site:

- Site Preparation:

- Clear and level the ground using a tractor for grading and flattening.

- Install necessary drainage systems to prevent waterlogging.

- Foundation and Frame Construction:

- Build the foundation, including concrete footings for stability and anchoring the frame.

- Erect the greenhouse frame and install all crossbars, purlins, and structural components.

- Cover Installation:

- Install the UV-resistant polyethylene cover or shade cloth on the greenhouse structure.

- Ensure the cover is tightly secured using double-channel systems and spring wires to prevent damage during windy conditions.

- Irrigation and Climate Control System Setup:

- Install the overhead irrigation system and connect it to water storage tanks and pumps.

- Set up climate control systems, including ventilation fans and thermostats, to maintain optimal conditions for tree growth.

- Internal Area Setup:

- Prepare the internal area with gravel and compacted material to ensure proper drainage and stability.

- Install stainless steel workstations and storage units for plant cutting and chemical storage.

5. Testing and Commissioning

Once the greenhouse is fully constructed, conduct testing and commissioning to ensure it operates efficiently:

- Irrigation System Testing:

- Test the irrigation system to ensure consistent water flow and coverage across the entire greenhouse.

- Adjust moisture sensors and automate irrigation cycles based on the needs of the tree crops.

- Climate Control Testing:

- Test the ventilation and climate control systems to maintain the desired temperature and humidity levels.

- Ensure proper operation of roll-up side walls, fans, and heating systems.

- Structural Inspection:

- Inspect the entire structure for stability, making sure all anchors and connections are secure.

- Review the greenhouse covering for any potential issues with tension or sealing.

6. Training and Handover

After successful commissioning, provide training for operators and workers:

- Staff Training:

- Train staff on the proper use and maintenance of the irrigation and climate control systems.

- Provide instructions on plant care, pruning, and handling of tools and chemicals.

- Handover Documentation:

- Supply all necessary documentation, including system manuals, warranty information, and maintenance schedules.

7. Maintenance and Support

Ensure ongoing support and maintenance for the greenhouse:

- Regular Inspections:

- Schedule routine inspections to check for structural integrity, covering wear, and the performance of irrigation and climate systems.

- Maintenance Contracts:

- Establish maintenance contracts for key components, including irrigation pumps, climate control systems, and greenhouse covering replacement.

Conclusion

By following this structured approach, the greenhouse design, build, procurement, and installation process can be effectively executed to provide a sustainable and efficient environment for tree crop cultivation. SPA.GD can optimize resources and ensure high yields through precise climate control, efficient water usage, and proper crop management techniques.

A template work plan

Installation Timeline for Greenhouse Design, Build, Procurement, and Installation

The timeline for designing, building, procuring, and installing a greenhouse for tree crop cultivation typically spans several months. Below is a suggested timeline that breaks down the key phases, assuming ideal conditions and no significant delays due to weather or shipping.

Phase 1: Project Planning and Feasibility Study (2-3 Weeks)

- Week 1-2:

- Conduct a feasibility study, site analysis, and soil testing.

- Finalize the selection of tree crops and greenhouse specifications (size, materials, irrigation, etc.).

- Review local building regulations and acquire any necessary permits.

- Develop a detailed project budget and funding plan.

- Week 3:

- Approve final designs and move forward with the procurement phase.

Phase 2: Greenhouse Design and Customization (3-4 Weeks)

- Week 4-5:

- Finalize the greenhouse design (structural frame, irrigation, ventilation, and climate control systems).

- Customizations for specific tree crop needs, including planting space, height, and workstations.

- Week 6:

- Secure design approvals and align specifications with procurement requirements.

Phase 3: Procurement of Materials and Equipment (4-6 Weeks)

- Week 7-8:

- Place orders for all major materials and equipment (greenhouse frame, covering, irrigation system, climate control system, and workstation equipment).

- Arrange for shipping and logistics, including any import clearances.

- Week 9-12:

- Monitor shipping progress and prepare the site for the arrival of materials.

- Ensure that all necessary tools and personnel are ready for the build phase.

Phase 4: Build and Installation (4-6 Weeks)

- Week 13-14: Site Preparation:

- Clear and level the site using tractors and appropriate tools.

- Complete ground preparation, including grading, drainage installation, and laying gravel and compacted material for internal and external areas.

- Week 15-16: Foundation and Structural Installation:

- Pour concrete for footings and install ground posts.

- Begin erecting the greenhouse frame and ensure all structural elements are securely anchored.

- Week 17-18: Cover Installation and Systems Setup:

- Install the UV-resistant polyethylene cover or shade cloth, securing it using channel systems and spring wires.

- Install the overhead irrigation system, climate control components, and roll-up sidewalls.

- Finalize internal setup, including workstations and chemical storage.

Phase 5: Testing and Commissioning (1-2 Weeks)

- Week 19:

- Conduct a full inspection of the structure, irrigation system, and climate control equipment.

- Test the irrigation system to ensure proper coverage and water distribution.

- Run climate control systems to verify temperature, humidity, and airflow are maintained at optimal levels.

- Week 20:

- Final adjustments to systems based on test results.

- Conduct staff training on operating irrigation and climate control systems and plant care.

Phase 6: Maintenance and Support Setup (Ongoing)

- Week 21 onwards:

- Establish routine inspection schedules.

- Ensure maintenance contracts for equipment are in place.

- Provide ongoing technical support and troubleshooting for greenhouse operations.

Total Estimated Timeline: 5-6 Months

This timeline reflects the typical duration from the initial feasibility study through to the commissioning and handover of a fully operational greenhouse. The timeline could be extended depending on site conditions, weather, procurement lead times, and any unforeseen delays.

Operational Framework and Model

Operational Plan for Greenhouse Operation and Training: SPA.GD Partnership

Following the successful installation of the greenhouse, SPA.GD will partner with the custodial owner to operate the facility for one year. The goal of this partnership is to train the custodial team in the methods of soursop replanting, ensure the proper hardening of plants, and provide ongoing support in key areas such as training, technology, and resource supply.

1. Objective

The primary objective is to transition operational control of the greenhouse to the custodial owner by providing training, resources, and technical assistance to ensure that the facility functions efficiently and meets the needs of tree crop cultivation, specifically soursop.

2. Duration and Scope

- Duration: 12 months (1 year 2024 Q4 of the year we should have the 2 houses establsihed.)

- Scope:

- Training in soursop plant propagation and hardening.

- Supply of essential materials and technology.

- Regular monitoring and technical support.

3. Phased Approach

The operational plan is divided into three key phases to ensure a gradual transfer of knowledge and responsibility.

Phase 1: Initial Operation and Training (Months 1-3)

Focus: Establishing systems, hands-on training, and initial production setup.

- Training and Capacity Building:

- SPA.GD experts will provide in-depth training on soursop replanting techniques, propagation, and hardening of plants.

- Hands-on sessions in cutting, planting, and preparing young shoots following SPA.GD’s “in-house” procedures.

- Greenhouse Management:

- Develop schedules for watering, fertilization, pruning, and pest control.

- Ensure proper use of the irrigation and climate control systems installed in the greenhouse.

- Technology Setup:

- Provide training on automated irrigation and climate monitoring systems, ensuring that the custodial team can operate the technology effectively.

- Initial Monitoring:

- SPA.GD will monitor the overall health of the plants and the effectiveness of the hardening process.

- SPA.GD will also ensure that the custodial team is familiar with proper plant care procedures and greenhouse management.

Phase 2: Gradual Transfer of Responsibility (Months 4-9)

Focus: Ongoing training, introduction of best practices, and incremental transfer of daily operations to the custodial team.

- Supervised Operations:

- The custodial team will gradually take over daily operations under SPA.GD supervision.

- Continued guidance on plant hardening processes, including environmental conditioning to strengthen plants before transplanting.

- Best Practices Introduction:

- Train custodial staff in best practices for plant care, including optimizing the use of water, fertilizer, and other inputs.

- Develop plant health monitoring protocols to detect and manage pests or diseases.

- Resource Support:

- SPA.GD will continue to supply essential materials, such as fertilizers, rooting powders, plant nutrients, and other required items during this phase.

- Monthly Reporting and Adjustments:

- SPA.GD will review progress reports and provide adjustments to ensure plant growth is optimized.

Phase 3: Full Custodial Operation with Technical Support (Months 10-12)

Focus: Transitioning complete control of the greenhouse to the custodial owner with ongoing technical support.

- Full Operational Control:

- The custodial team will take over full responsibility for managing greenhouse operations, including plant propagation, irrigation control, and climate monitoring.

- Final Training Sessions:

- SPA.GD will provide any refresher training sessions or new skill development as necessary.

- Training for staff on troubleshooting irrigation and climate control technology.

- Technical Support:

- SPA.GD will offer remote support and site visits (as needed) to address any operational challenges or issues.

- Custodial team will receive detailed guidelines for maintaining plant quality and hardening procedures.

- Final Review and Handover:

- A final operational review will be conducted to assess the readiness of the custodial team to manage the facility independently.

- SPA.GD will prepare a detailed handover report with recommendations for ongoing operations.

4. Key Components of Support

SPA.GD will provide the following types of support throughout the year to ensure the smooth operation of the greenhouse:

- Training:

- Regular hands-on and theoretical training sessions in propagation, plant care, and greenhouse management.

- Resource Supply:

- Provision of essential materials, including:

- Rooting powders, fertilizers, and plant nutrients.

- Pest and disease control products.

- Replacement parts for irrigation and climate control systems (if needed).

- Technology and Maintenance:

- Installation and training on the use of automated systems such as:

- Overhead irrigation systems for efficient water distribution.

- Climate control systems (ventilation, temperature control).

- Ongoing technical support for the installed systems, including software and hardware troubleshooting.

- Plant Hardening Protocols:

- Detailed protocols for hardening soursop plants before transplanting, including:

- Gradual exposure to natural conditions (light, temperature).

- Techniques to improve plant resilience.

- Monitoring and Reporting:

- SPA.GD will conduct monthly progress checks and provide feedback on plant growth and greenhouse operations.

- Regular reports will include any suggested operational adjustments to improve plant production.

5. Monitoring and Evaluation

SPA.GD will use a continuous monitoring and evaluation system to track progress and make adjustments throughout the operational year:

- Monthly Monitoring Reports:

- Each month, SPA.GD and the custodial team will submit progress reports detailing the health of the plants, greenhouse operations, and any issues encountered.

- Quarterly Performance Reviews:

- A more comprehensive performance review will be conducted quarterly to evaluate the overall efficiency of the greenhouse operations and plant hardening protocols.

- Final Evaluation:

- A final evaluation will be conducted in the 12th month to assess the readiness of the custodial team to manage the greenhouse independently and to determine the success of the training and support provided.

6. Exit Strategy

At the end of the 12-month period, SPA.GD will transition the greenhouse fully to the custodial owner:

- Complete Handover: The custodial team will assume full responsibility for greenhouse operations.

- Final Training and Documentation: SPA.GD will provide comprehensive documentation on greenhouse operation, troubleshooting, and plant care best practices.

- Ongoing Support (if required): An optional maintenance contract can be established for ongoing technical support and resource supply if needed.

Conclusion

This operational plan ensures that the greenhouse will be fully functional and capable of supporting soursop replanting within one year, with the custodial owner trained in SPA.GD’s proprietary methods for plant propagation, hardening, and care. Through continuous support and resource provision, the custodial team will gain the skills and knowledge needed to run the greenhouse independently while maintaining high plant productivity.

Bills of Materials for Planting House for Sour Sop.

We can source our materials from farmersfriend.com

The Black Covering for the Ground.

Shipping to the USA will take place to a Drop Shipping in Miami. Here there will check and confirm the order, before shipping out to the Island of Grenada to SPA.

SPA will need to apply for concession to clear the two 60 feet green houses.

Total estimated charge will be USD12,000.00 per unit arrived to the location in Grenada. ( Cost includes all the necessary tools ordered with the tunnel order)

Based on the document content, here’s a suggested Table of Contents for the SPA Packing House Energy and CO2 Reduction Project:

Table of Contents

- Introduction

- Background of SPA (Simple Pure AgroProcessing)

- SPA Sour Sop Processing Overview

- Importance of Export Markets

- Project Overview

- Development of the Packing House with Low Carbon Footprint

- Focus on Sustainability and Global Standards

- Component 1: Green Energy for SPA Packing House

- Installation of Climate-Friendly Energy System

- Solar System Design and Capacity

- Infrastructural Upgrades for Energy Efficiency

- Component 2: SPA Building and Packaging Facility for Soursop and Fruits

- Project Scope and Estimated Cost

- Redesign, Build, and Repair of Munich St. Andrew’s SPA Facility

- Current Project Status and Funding Needs

- Component 3: Shade and Planting House for Soursop Trees

- Objective and Project Overview

- Establishing Two Shade and Planting Houses

- Project Scope, Estimate, and Target Locations

- Goals for Supporting the Soursop Industry in Grenada

- Expected Outcomes

- Environmental Sustainability

- Economic Impact and Agricultural Innovation

- Project Financial Summary

- Detailed Breakdown of Costs

- Contingency Plans and Total Project Estimate

- Additional Considerations

- Regulatory and Safety Compliance

- Future Expansion and Agricultural Techniques